Revolutionizing Industries: The Impact of Robotics on Modern Workplaces

As we move further into the 21st century, the influence of robotics on modern workplaces is becoming increasingly evident. Transformative technologies, driven by advancements in robotics, are redefining how industries operate, enhancing efficiency, and reshaping the workforce landscape. This article explores the profound impact of robotics across various sectors, highlighting current trends, statistics, and real-world examples.

The Integration of Robotics into Various Industries

Robotics have permeated several sectors including manufacturing, healthcare, logistics, and even agriculture. These automated systems provide significant advantages, such as improved precision and reduced labor costs, allowing businesses to scale operations rapidly.

Manufacturing: Precision and Efficiency

Robotics has been a game-changer for the manufacturing sector, where precision automation leads to higher quality products at a reduced cost. According to the International Federation of Robotics (IFR), the global stock of industrial robots reached approximately 3 million units in 2021, and it is projected to grow to 4 million by 2025. These machines can perform tasks such as welding, painting, and assembly with remarkable accuracy, minimizing human error and enhancing productivity.

Healthcare: Saving Lives Through Automation

The application of robotics in healthcare is revolutionizing patient care. Surgical robots, like the da Vinci Surgical System, allow surgeons to perform minimally invasive procedures with increased accuracy. A study by the American Medical Association revealed that robotic-assisted surgeries resulted in a 20% reduction in recovery time for patients compared to traditional methods. This not only enhances patient outcomes but also decreases the strain on healthcare resources.

Logistics and Supply Chain: Streamlining Operations

The logistics industry is embracing robotics with autonomous vehicles and drones. A notable example is Amazon’s use of Kiva robots in its warehouses, which has reportedly enhanced inventory management and reduced order fulfillment time by up to 50%. The growing reliance on robotics in logistics reflects an increasing trend toward automation in supply chains, addressing labor shortages and improving operational efficiency.

The Workforce Transformation: Navigating the Future

While the adoption of robotics offers numerous benefits, it also brings challenges, particularly concerning the workforce. There is a fear that automation may lead to significant job displacement; however, studies suggest a more nuanced outcome. The World Economic Forum estimated that by 2025, automation could displace 85 million jobs while simultaneously creating 97 million new roles that require more advanced skills.

Upskilling: Preparing for an Automated Future

To thrive in an era dominated by robotics, upskilling the current workforce is imperative. Companies and educational institutions are increasingly collaborating to provide training in robotics programming, artificial intelligence, and data analysis. For instance, many organizations are adopting hybrid workforce models, where humans and robots work side by side, leveraging the strengths of both.

The Human Touch: A Case for Collaboration

Robotics should not be viewed as a replacement for human capabilities but rather as a complementary force that enhances the human workforce. A relevant analogy is the coexistence of calculators and mathematicians; calculators do not eliminate the need for skilled individuals but instead facilitate more complex problem-solving.

Current Trends and Future Outlook

As the integration of robotics continues, several trends are emerging:

- Increased Investments: Venture capital in robotics has surged, reaching $16 billion in 2021, a testament to the technology’s potential.

- Enhanced AI Integration: Robotics is increasingly being paired with artificial intelligence, enabling machines to learn from their environments and improve their functions autonomously.

- Sustainability Focus: Robotics is playing a crucial role in promoting sustainable industrial practices, such as energy-efficient production methods and waste reduction.

The future looks promising as innovators push the boundaries of what robotics can achieve. Companies that prioritize adopting these technologies will likely gain a competitive edge in their respective markets.

Conclusion

The impact of robotics on modern workplaces is profound, offering significant benefits to various industries, reshaping the workforce, and driving economic growth. As we adapt to this rapidly evolving landscape, it is crucial that we embrace the opportunities that robotics presents while also addressing the challenges that accompany it.

For further reading on robotics and their impact on specific industries, consider checking out our articles on The Future of Robotics in Manufacturing and How Automation Is Transforming Healthcare.

For additional insights into the robotics industry, visit the International Federation of Robotics and review their latest reports on robotic adoption and trends.

Suggested Multimedia

-

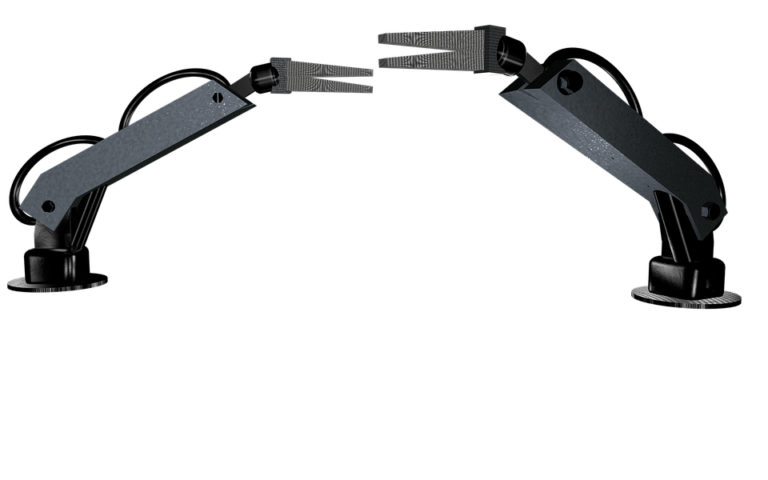

Image 1: An industrial robot in action in a manufacturing plant.

Alt Text: Industrial robots transforming manufacturing processes via automation.

- Image 2: A surgeon using a robotic surgical system in an operating room.

Alt Text: Robotic-assisted surgery demonstrating technology’s impact on healthcare.

By understanding and leveraging the potential of robotics, we can not only streamline operations but also create a more skilled and adaptable workforce ready to meet the challenges ahead.